Craftsmanship & technique

We’re choosing to stay true to our roots and still create fine pottery with generational methods by hand. This is something mass production can’t replace.

Producing clay tableware, A to Z.

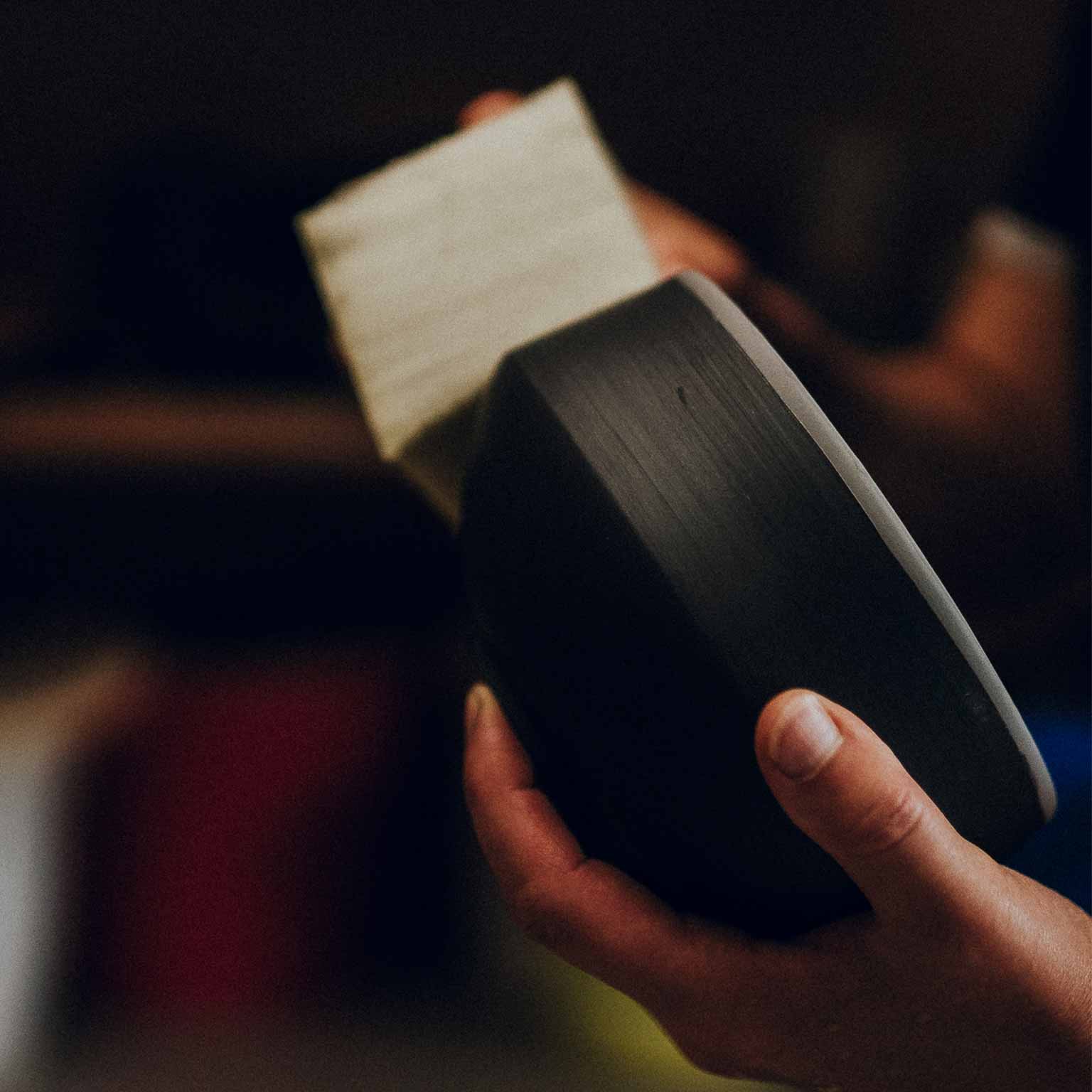

Let us take you on a journey through our pottery. We do everything in-house, by hand. It all starts with the clay that is obtained in a nearby clay-pit. We then prepare the clay by adding water and mixing it. Once our clay is the perfect consistency, it’s ready for shaping. Our artists use the potter's wheel and the process called jiggering to give our products their distinctive design and clean lines. Then it’s time to dry each piece before firing them in a kiln. Our kiln runs on electricity, meaning it takes significantly less time to heat up. When all the pieces are fired at 1000°. Some might say the most tedious step is polishing each piece to achieve our signature texture. We find it therapeutic. All there’s left to do is glaze the inside and seal the final result.

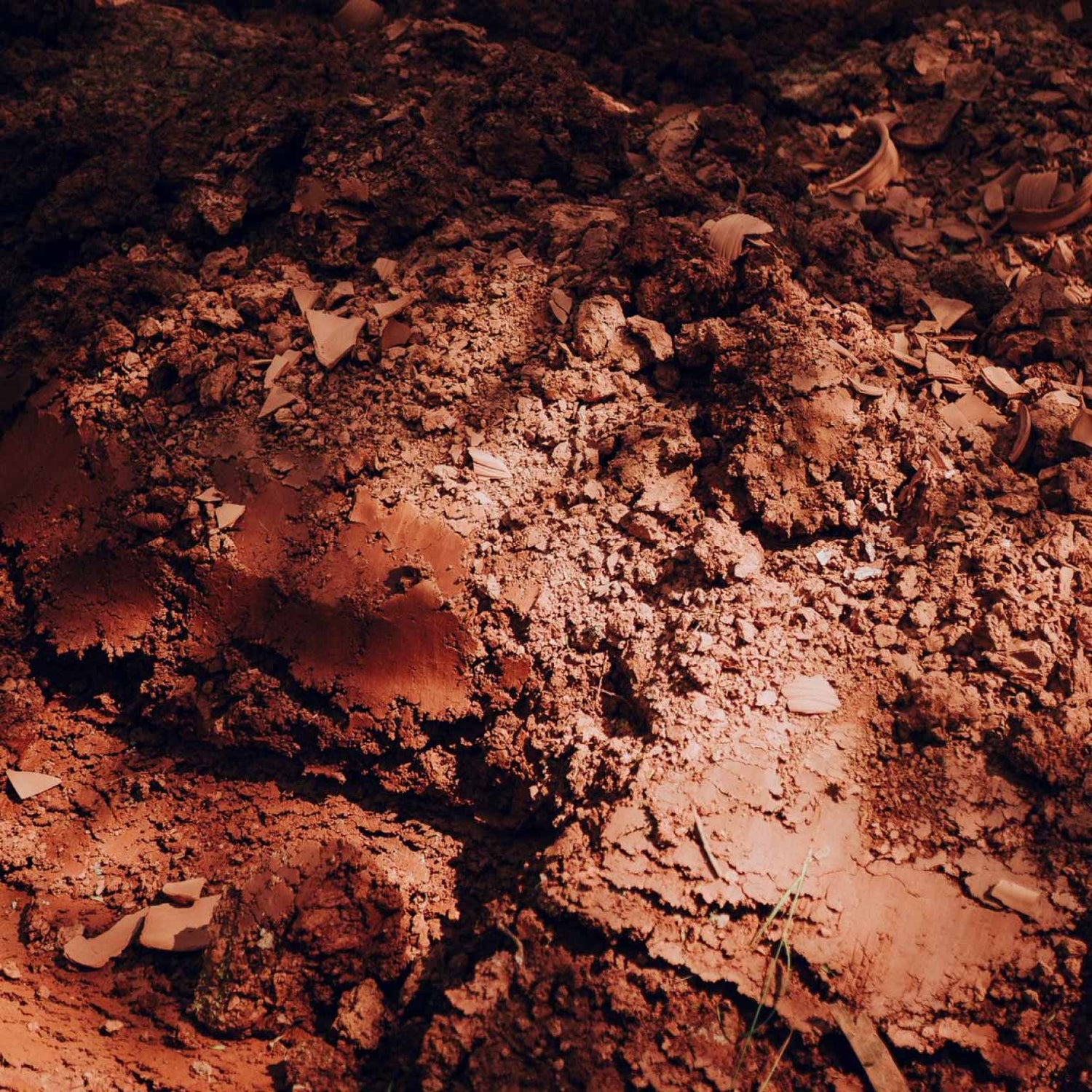

Radiant red clay

We work with natural red clay, recognised for its distinctive colour caused by iron oxide. Valued by potters for generations, this clay is known for its strength, durability, and resistance to heat. While traditionally used in brick-making, through our craftsmanship and innovation it has been transformed into elegant and enduring tableware.

Designer spotlight

Laima brings quiet beauty into everyday life. Known for her contemporary spin on minimalist, Nordic design, she highlights quality, durability, and handmade craftsmanship. Our shared values toward the craft, have resulted in two beautiful collaboration collections - Eclipse and Eclipse Gold. Let’s honor nature by highlighting its magnificent materials.

-

Vase · Eclipse Gold

Regular price €115,00 EURRegular priceUnit price per€115,00 EURSale price €115,00 EUR -

Vase · Eclipse

Regular price €95,00 EURRegular priceUnit price per€95,00 EURSale price €95,00 EUR -

Sold out

Sold outServing plate · Eclipse Gold

Regular price €102,00 EURRegular priceUnit price per -

Serving plate · Eclipse

Regular price €75,00 EURRegular priceUnit price per€75,00 EURSale price €75,00 EUR -

No.9- Lunch Set with a Mug · Eclipse

Regular price €130,50 EURRegular priceUnit price per€145,00 EURSale price €130,50 EUR-10% -

No.8- Lunch Set · Eclipse

Regular price €108,00 EURRegular priceUnit price per€120,00 EURSale price €108,00 EUR-10% -

No.7- Bowl Set · Eclipse

Regular price €93,60 EURRegular priceUnit price per€104,00 EURSale price €93,60 EUR-10% -

No.10- Espresso Set with a Plate · Eclipse

Regular price €73,80 EURRegular priceUnit price per€82,00 EURSale price €73,80 EUR-10% -

Mug · Eclipse Gold

Regular price €31,00 EURRegular priceUnit price per€31,00 EURSale price €31,00 EUR -

Mug · Eclipse

Regular price €25,00 EURRegular priceUnit price per€25,00 EURSale price €25,00 EUR -

Lunch bowl · Eclipse Gold

Regular price €57,00 EURRegular priceUnit price per€57,00 EURSale price €57,00 EUR -

Lunch bowl · Eclipse

Regular price €47,00 EURRegular priceUnit price per€47,00 EURSale price €47,00 EUR